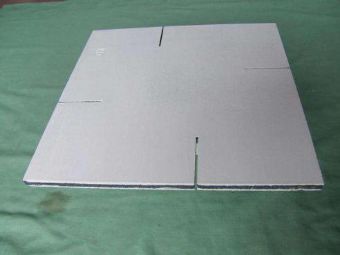

Silicon Carbide Refractory decks

Silicon carbide refractory decks are made of high-purity silicon carbide and ultra-fine powder by vibration molding and high-temperature sintering. They have the advantages of good high-temperature thermal conductivity and high-temperature load-bearing, and are suitable for various building ceramics, sanitary ceramics, household ceramics, electric porcelain refractories and powder metallurgy sintering furnaces.

Category:

Description

| Item | Unit | Index | |

| Physical properties | SIC Chemical composition≥ | % | 90 |

| Max. Service temp. | ℃ | 1550 | |

| Refractoriness ≥ | SK | 39 | |

| 2kg/cm Refractoriness under load T2 ≥ | ℃ | 1750 | |

| Modulus of rupture under room temp. ≥ | kg/cm2 | 500 | |

| Modulus of rupture at 1400℃≥ | kg/cm2 | 550 | |

| Compressive strength ≥ | kg/cm2 | 1300 | |

| Thermal expansion at 1000℃ | % | 0.42-0.48 | |

| Apparent porosity | % | 7-8 | |

| Bulk density | g/cm3 | 2.70-2.75 | |

| Thermal conductivity at1000 ℃ | Kcal/m.hr.℃ | 13.5-14.5 | |

| As to the above functional characteristics, they can be designed upon the customer’s request. | |||

Keywords:

refractory

ge

cm2

kg

rupture

thermal

at

temp.

refractoriness

of

Previous:

Online Inquiry