Foundry Market to Make Great Impact in near Future by 2024

The MarketWatch News Department was not involved in the creation of this content.

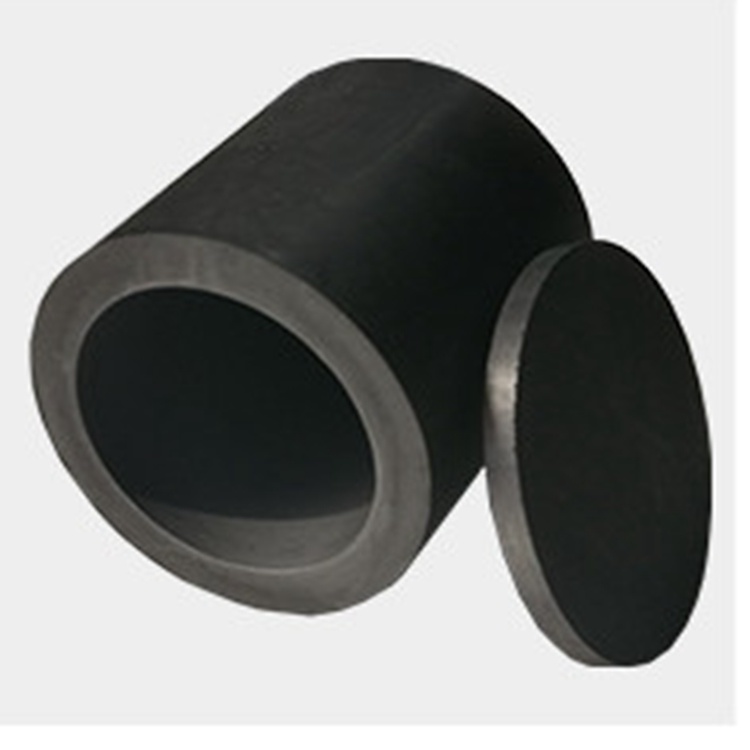

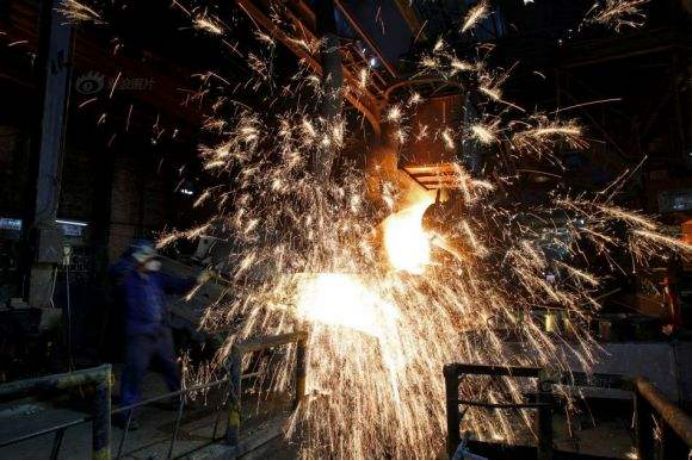

May 26, 2020 (Stockestic via COMTEX) -- A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals processed are aluminum and cast iron.

Big Market Research has added a report, titled, "Foundry Market" The report not only provides a comprehensive analysis of market overview and dynamics for the historical period, 2020-2024, but also offers global and regional forecasts on market value, volume production, and consumption during the future period, 2020-2024. The report also analyzes the key market players, especially the distributors, along with the industrial chain structure. The evolution of market trends is discussed along with the competitive landscape in various regions, which would help top and emerging market players to determine the lucrative investment pockets.

"Our analysis involves the study of the market taking into consideration the impact of the COVID-19 pandemic. Please get in touch with us to get your hands on an exhaustive coverage of the impact of the current situation on the market. Our expert team of analysts will provide as per report customized to your requirement."

R The report begins with a brief introduction and market overview, in which the Foundry industry is first defined before estimating its market scope and size. Next, the report elaborates on the market scope and market size estimation. This is followed by an overview of the market segmentations such as type, application, and region. The drivers, limitations, and opportunities are listed for the Foundry industry, followed by industry news and policies.

The report performs an industry chain analysis, focusing on upstream raw material suppliers and major downstream buyers. The data is highlighted through the use of tables and figures, which also include manufacturing cost structure and market channel analysis. Major players involved in the Foundry industry are also delineated, along with their market share and product types.

The report segments the global Foundry market based on factors such as type, application, and region. For the historic period, extensive insights on value, market share, production, growth rate, and price analysis for each sub-segment is offered by the report. Additionally, the report also delves into regional production, consumption, export, and import for the historic period. Finally, the current market status and SWOT analysis for each region are elaborated, which would assist market players to gain a competitive edge by determining the dominant segments.

The key players profiled in this report include: Ashok Leyland Ltd., DCM Ltd., Electrosteel Castings Ltd., Jayaswal Neco Industries Ltd., Kirloskar Ferrous Industries Ltd., Mahindra CIE Automotive Ltd., Nelcast Ltd., Sanmar Group, Tata Metaliks Ltd., Tata Motors Ltd.

The key product type of Foundry market are: Gray iron casting foundry market, Non-ferrous casting foundry market, Ductile iron casting foundry market, Steel casting foundry market, Malleable casting foundry market.

The end users/applications listed in the report are: Semiconductor foundry market, Consumer electronics foundry market, automotive industry foundry market, Electrical and construction industry foundry market, Industrial machinery industry foundry market.

Based on region the report evaluates the market across different region such as: North America, Europe, China, Japan, Middle East & Africa, India, and South America.

For the future period, sound forecasts on market value and volume are offered for each type and application. In the same period, the report also provides a detailed analysis of market value and consumption for each region. These insights are helpful in devising strategies for the future and take necessary steps.

2020-09-09